The Backbone of Modern Infrastructure: An In-Depth Exploration of Cable Tray Systems

In today's interconnected world, efficient cable management is critical for power and data systems across industries. Modern cable trays provide versatile, safe, and cost-effective solutions that consistently outperform traditional conduits in both performance and long-term value. As infrastructure demands grow increasingly complex, understanding the full spectrum of cable tray options becomes essential for engineers, facility managers, and project planners seeking optimized solutions.

Here, we explore key types and comprehensive benefits of cable tray systems, highlighting how these engineered solutions address contemporary challenges in cable management.

Types of Cable Trays

1.Ladder-Type Trays

Characterized by parallel side rails connected by rungs at regular intervals, these systems offer exceptional strength-to-weight ratios. Their open design maximizes airflow around cables, reducing thermal buildup in high-density installations. This makes them particularly suitable for long-span applications in data centers and industrial facilities where both structural integrity and thermal management are paramount.

2.Solid Bottom Trays

Featuring a continuous metal surface without ventilation openings, these trays provide complete physical protection against dust, moisture, and falling debris. Their enclosed design makes them ideal for environments requiring contamination control, such as food processing plants, pharmaceutical facilities, and outdoor installations where weather resistance is crucial.

3.Trough-Type (Perforated) Trays

Combining the benefits of both ladder and solid designs, these trays feature a perforated bottom with raised sides. This configuration offers balanced protection and ventilation while providing better support for smaller diameter cables than ladder trays. Their versatility makes them popular in commercial buildings, hospitals, and educational institutions for both power and telecommunications applications.

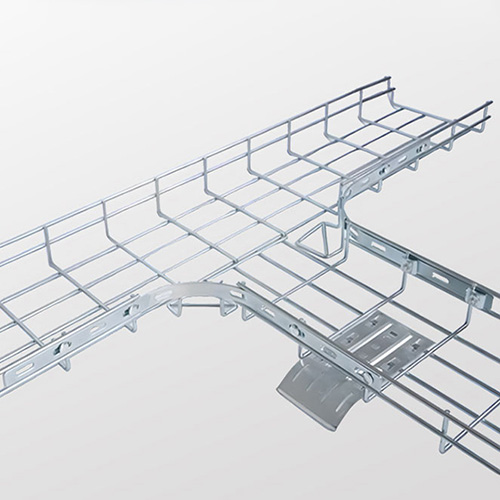

4.Wire Mesh Trays

Constructed from welded steel wires in a grid pattern, these lightweight systems offer maximum flexibility and ventilation. Their open design allows for easy cable access from any direction and facilitates excellent heat dissipation. These characteristics make them particularly valuable in data centers, office buildings, and environments where cable configurations change frequently.5.Channel-Type Trays

These simple U-shaped channels provide economical support for light cable loads over shorter distances. Often used as auxiliary systems, they're perfect for branch circuit connections, control wiring, and localized cable management. Their straightforward design allows for quick installation and modification when requirements change.

Material selection further enhances performance, with galvanized steel providing robust protection for most environments, aluminum offering excellent corrosion resistance with reduced weight, and stainless steel delivering superior performance in highly corrosive or hygienically sensitive applications.

Key Advantages

1.Cost & Time Savings: Installation proves significantly faster than traditional conduit systems, reducing labor costs by up to 40% in many applications. The modular nature allows for easier modifications and expansions without major system overhauls, providing substantial long-term savings.

2.Enhanced Thermal Performance: Open designs actively dissipate heat, preventing cable overheating that can degrade insulation and reduce lifespan. Improved cooling can increase cable ampacity by 10-15% compared to enclosed systems, allowing for more efficient power distribution.

3.Easy Maintenance & Safety: Complete cable visibility simplifies identification, inspection, and troubleshooting. Organized routing reduces workplace hazards and supports compliance with safety regulations. The accessibility significantly reduces downtime during maintenance operations.

4.Flexibility & Scalability: Systems easily adapt to layout changes and future expansions. This scalability supports evolving infrastructure needs without requiring complete system replacement, making cable trays a sustainable long-term investment.

5.Optimized Cable Performance: Proper cable support prevents sagging and excessive bending, maintaining signal integrity in data cables and reducing mechanical stress on power cables. Segregation capabilities allow for proper separation between different cable types, minimizing interference.

Conclusion

Cable trays have evolved from simple support structures to intelligent infrastructure solutions that actively contribute to system reliability, efficiency, and adaptability. Their engineered designs address thermal management, accessibility, and future-proofing in ways traditional methods cannot match.

By selecting the appropriate tray type and material for specific applications, industries can build safer, more sustainable facilities ready to meet tomorrow's infrastructure demands while optimizing today's operational efficiency. As cable density continues to increase across all sectors, cable tray systems stand as essential components in creating resilient, manageable, and scalable infrastructure for the connected age.